How to Use DTF

Direct to film (DTF) printing is rapidly becoming a popular option for companies looking to grow their decorated clothing business. Take a look at our guide to this exciting new technology below...

1. Place a sheet of DTF paper with print face up on the platen of the Epson SC-F2100. Use tape to hold paper in place.

2. Using the recommended settings on garment creator, send your design to print.

3. Once printed, carefully take the film sheet off the printer. Transfer to a tray of DTF hotmelt powder and coat the design evenly. We recommend flicking the film to remove any excess powder.

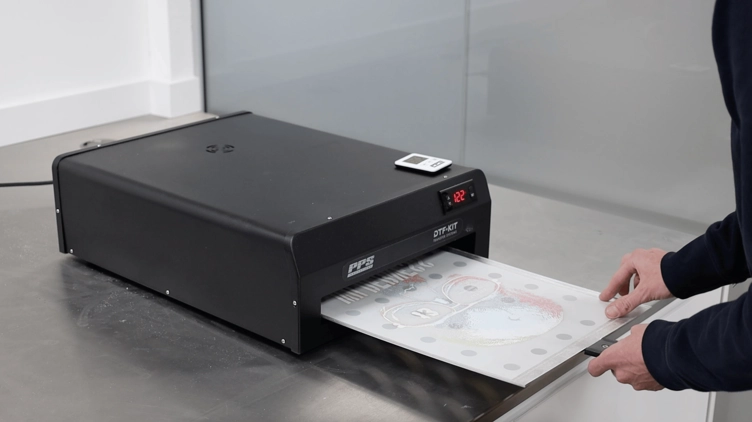

4. Using a DTF cure oven or a tunnel oven, cure the hotmelt powder until it melts and has an orange peel effect appearance. On average, this takes 3-4 minutes.

5. Pre-press the garment to remove any moisture and creases from the fabric. Position the film with the melted glue side down on the garment, cover with a silicone sheet then press for the recommended time.

6. Once pressed, remove the garment from the heat press and peel cold.

7. Return the garment to the heat press, cover with the silicone sheet and re-press the garment for the time recommended. Your DTF print is now complete.