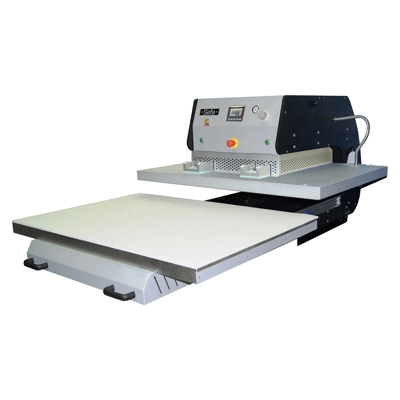

Alpha Industrial Pneumatic Series 7 Heat Press - 120 x 170cm

The Alpha Industrial Pneumatic Series 7 heat transfer machine is a pneumatically operated twin reciprocating table heat press for transfer printing and is ideal for very high volume industrial production with low operator fatigue.

The Alpha Industrial Pneumatic Series 7 is suitable for thermal and low temperature transferring and is available with reciprocating tables and automatic operation.

Key Features

The Alpha Industrial Flatbed Series 7 Press boasts an impressive range of features including:

PLC control system.

Cartridge based, replaceable heating elements.

Twin button control system ensures the operators hands are clear of the pressing area.

Manual or automatic operating modes with auto open release system.

Heat plate will not operate until directly aligned over the lower table.

Fully adjustable temperature and pressure control.

Electronic countdown timer.

Emergency stop button that shuts off machine operation.

Inbuilt thermal cut out on the heating element shuts off power to heating element should the temperature exceed 235°C +/- 15°C (455°F +/-27°F).

120 cm x 170 cm pressing area

The large pressing area measuring 80 cm x 100 cm, with twin reciprocating sliding lower tables. This enables operators to be preparing the next item to be pressed, whilst the first table is being pressed therefore maximising productivity.

Ideally suited for printing garments and large panels

Perfect for Sportswear, Flags, Upholstery Materials and Soft/ Hard signage applications.

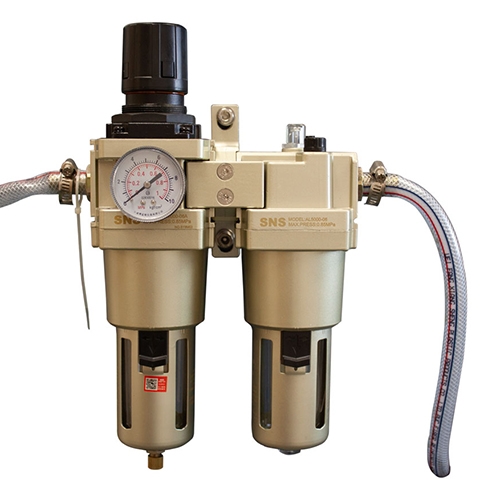

Easily replicate exact pressure

The pneumatic operation means that you can easily replicate exact pressure with every press cycle and operator fatigue is kept to a minimum, resulting in improved operator output and reducing mistakes due to fatigue.

Innovative cartridge based heating element

The Alpha Industrial Series 7 range has an innovative cartridge based heating element that replaces the older single continuous cast in aluminium style element. The benefit of the cartridge system is that it has multiple, individually replaceable elements, allowing replacement of just a single cartridge should the need arise.

Simple, fully adjustable air pressure gauge

The operator controls the pressure via a simple, fully adjustable air pressure gauge and locking air pressure control. Fully adjustable time and temperature are set via the controller and the LED display features a countdown timer.

PLC Digital Controller

The Alpha Industrial Flatbed Series 7 Press features a PLC Controller (Programmable Logic Controller) that allows for ultimate control over heat and dwell settings, with a large LCD screen displaying all data clearly for the benefit of the operator.

Twin Reciprocating Table

The operator loads the machine via the sliding lower table. Once loaded the operator sends the loaded bed into the press and commences the pressing cycle. The second bed slides out into the loading position and enables the operator to commence preparing the next item to be pressed, whilst the first bed is being pressed.

Finance Calculator

Finance options are available for this product. These may vary on a case by case basis and should be discussed with a member of the Xpres team.

Xpres are not the lender, but are acting on the customers behalf to arrange contact between our finance partners.

| Weekly Equivalent | £86.77 |

|---|---|

| 24 Monthly Payments | £375.99 |

| Total Cost | £9023.76 |

| Tax Relief @ 19% | £1714.51 |

| Cost of Finance | £7309.25 |

Machine comes with 12 Months Return to Base Warranty (Please view our warranty terms HERE for further details).

| Working Area (W x H x D): | 211 x 155 x 313 cm |

| Weight: | Gross 1390 Kg / Net 1114 Kg |

| Size Export Packed (L x W x H): | 224 x 215 x 187 cm |

| Power Requirements: | 380 - 440 Volts AC 3-Phase (Neutral + Earth) / 18 kW / 34 Amps (27 Amps per Phase) |

| Fuse: | 34 Amps |

| Heat Element: | Cartridge Elements (x6) - Replaceable |

| Table Size (L x W): | 120 cm x 170 cm (x2) |

| Maximum compressed air supply: | 6 bar. max. (87 psi. max) |

| Suggested compressed air supply: | 5 bar. (65 psi) |

| Compressed air consumption: | 125 litres/min (4.41 cu. ft./min) @ 5 bar. |

| Frame Material: | Steel |

| Control Unit: | PLC Control |

| Working Temperature: | 70 - 225°C |

| Display Timer Range: | 0 - 999 sec |

| Warranty: | 12 months (machine and heating element) |